|

XRD Graphite Manufacturing Co., Ltd.

|

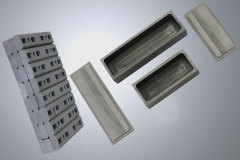

Graphite machining graphite impeller mold

| Price: | 500.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

In recent years, the rapid development of the mold industry, graphite materials, new processes and an increasing number of mold factories continue to

In recent years, the rapid development of the mold industry, graphite materials, new processes and an increasing number of mold factories continue to hit the mold market. Graphite, with its good physical and chemical properties, has gradually become the preferred material for mold making.

Dies are the most widely used basic process equipment in industrial production. The die and mold industry is the basic industry of the national economy. In modern industrial production, product parts are widely used in stamping, forging, die-casting, extrusion, plastic injection or other forming processing methods, and are matched with the forming dies to form blanks into parts that meet the requirements of the product. The various tools and products used in our daily production and life are as large as the base of the machine tool, the shell of the machine body, and the size of a single head screw, button, and shell of various household appliances, all of which are closely related to the mold. The shape of the mold determines the shape of these products. The quality and accuracy of the mold determines the quality of these products. In recent years, the rapid development of the mold industry, graphite materials, new processes and an increasing number of mold factories continue to hit the mold market. Graphite, with its good physical and chemical properties, has gradually become the preferred material for mold making.

At present, graphite molds are widely used in the following aspects:

Artificial graphite as a continuous casting or semi-continuous casting mold for non-ferrous metals is considered to be the most suitable material. Production practice shows that due to the use of graphite molds, due to its good thermal conductivity (thermal conductivity determines the solidification rate of the metal or alloy), the self-lubricating properties of the mold and other factors, not only increase the speed of the mold, but also due to the size of the ingot Accurate, smooth surface, uniform crystal structure, can be directly processed in the next process. This not only greatly improved the yield, reduced the loss of waste products, but also greatly improved product quality. Continuous casting methods include vertical continuous casting and horizontal continuous casting.

Die for pressure casting

Artificial graphite materials have been successfully used in the press casting of non-ferrous metals. For example, castings of zinc alloys and copper alloys produced using a die for pressure casting made of artificial graphite materials have been used in automobile parts and the like.

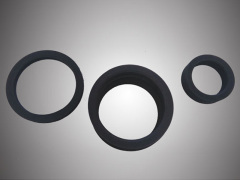

Centrifugal graphite mold

Graphite molds have been successfully applied to centrifugal casting. The United States has used centrifugal graphite molds with a wall thickness of 25 mm or more to centrifugally cast bronze sleeves. In order to prevent burning of artificial graphite molds, certain oxidation prevention measures may be taken. After casting a certain number of castings, if the inner surface of the casting mold is found to be burned, the size of the inner hole of the casting mold can be enlarged to cast a large-size casing.

Hot pressing die mold

The artificial graphite hot stamping die has the following characteristics in the pressure sintering of cemented carbide: First, if the pressing temperature is increased to 1350-1450 degrees, the required unit pressure can be reduced to 67-100 kgf/cm2. (that is, 1/10 of the cold pressing pressure) can be; Second, pressing and heating are performed in the same process, and a compact sintered body can be obtained after a short time of sintering.

Glass mold

Since graphite materials have chemical stability, are not easily infiltrated by the molten glass, do not change the composition of the glass, the graphite material has good thermal shock resistance, and the dimensional change with temperature is small, so in recent years it has become an indispensable mold in glass manufacturing. Materials can be used to make glass tubes, elbows, funnels and other various shaped glass bottles.

Sintering molds and other diamond sintered molds

Using the characteristics of extremely small thermal deformation of the artificial graphite material, the sintered mold and the stent of the transistor can be manufactured, and it has been widely used. It has become an indispensable material for the development of the semiconductor industry. In addition, graphite molds are also used in casting molds for cast iron, durable molds for various non-ferrous metals, casting molds for cast steel, molds for heat-resistant metals (titanium, zirconium, molybdenum, etc.), and aluminum for welding rails. Heat-welded molds. The graphite die for hot-pressed and sintered diamond tools is responsible for the dual functions of heating elements and die support in the diamond tool manufacturing process. The quality of the graphite die directly affects the dimensional accuracy and appearance of the diamond tools. Hot-press sintering process requirements: temperature reached (1 000 ± 2) °C, molding pressure 16 ~ 50 MPa, insulation holding pressure time is 15 ~ 30 min, the environment is non-vacuum state. Under this working condition, it is required that the graphite mold of the molding and heating element has electrical conductivity, high resistivity, sufficient mechanical strength, and also needs good oxidation resistance and a long service life to ensure the diamond The dimensional accuracy and excellent performance of the tool. At present, the graphite mold materials used in the manufacture of diamond tools are mainly graphite materials with ultrafine grain structure, high purity and high graphitization degree, and their average particle size is less than 15 μm, even 10 μm or less, and the medium pore size is less than 2 μm. The graphite mold made of this carbon raw material has a small porosity, a compact structure, a high surface finish, and strong oxidation resistance, and the average service life can reach 30-40 times. Diamond molds require high hardness, good oxidation resistance, and high processing accuracy. The use of high quality graphite raw materials greatly extends the service life of the mold and improves the oxidation resistance.