|

XRD Graphite Manufacturing Co., Ltd.

|

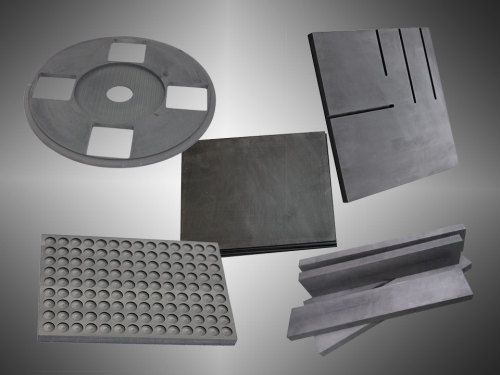

High purity graphite plate

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Graphite plate has wear resistance, high temperature resistance and low burning. It has good chemical stability at normal temperature, corrosion resis

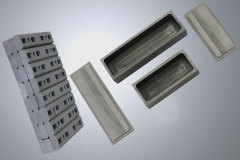

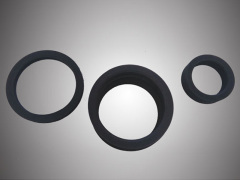

XRD Graphite specializes in the production of graphite plate, graphite bearing, graphite hot zone, graphite rotors, graphite crucibles, graphite boats, graphite tubes, graphite rods, graphite baffles, graphite flow channels, graphite plates, etc.XRD Graphite's own special graphite production line can provide more than one hundred different specifications of graphite raw materials. According to the needs of different industries for different graphite materials, select specific materials for customers, after special treatment such as oxidation resistance, effectively extend the life of graphite machining products, improve product cost performance.

Graphite plate introduction:

Graphite plate has wear resistance, high temperature resistance and low burning. It has good chemical stability at normal temperature, corrosion resistance to acids, alkalis and organic solvents, excellent electrical and thermal conductivity, and long service life.

Application scope of graphite plate

Graphite plates are widely used in electronics, electric power, metallurgy and other industries. Graphite plate is used as a lubricating material in many mechanical equipment. It can slide at a speed of 100 m/s in the temperature range of -200 to 2 000 °C. No lubrication is needed or used. Oil, can achieve a good lubrication effect. The graphite plate has a good thermal conductivity. It is more effective for strengthening the bottom of the furnace, reducing the temperature at the bottom of the furnace, and reducing the erosion at the bottom of the furnace. It is suitable for the bottom of the blast furnace and the belly of the furnace. The graphite plate can be used as an electroconductive anode for electrolyzing salt solution to prepare caustic soda, and can also be used for sewage treatment in chemical, electronic and textile industries.

Advantage of XRD graphite's graphite plate:

Selection of raw materials:

Special graphite developed by XRD Graphite specialty is used as raw material, which has high mechanical strength, good self-lubrication performance, high temperature creep resistance, high coefficient of friction, high coefficient of thermal conductivity and low coefficient of thermal expansion.

Product processing:

strictly according to the customer's drawings of high-precision processing, the installation of each component closely with each other, high concentricity;

Impregnating and anti-oxidation:

the raw materials were treated with anti-oxidation by many times of impregnation and roasting, so that the graphite materials were filled with anti-oxidants and the surface was covered with anti-oxidants, which effectively improved the high temperature resistance, anti-oxidation, anti-erosion performance of graphite plates, and greatly prolonged their service life.

XRD Graphite focus on supply large quantities of stable quality graphite products to customers with graphitization or graphite machining needs. To date, XRD Graphite has forged lasting relationships with key customers in over 30 countries and be considered as one of the leading supplier of graphite manufacturing and machining products in China. XRD Graphite is to constantly provide superior customer service while delivering stable quality graphite products in mass production.