|

XRD Graphite Manufacturing Co., Ltd.

|

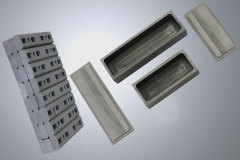

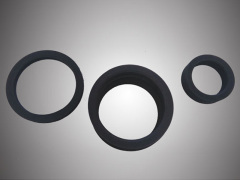

Graphite Bearing sliding bearings

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Graphite sliding bearings are mainly made of graphite, and have strong self-lubrication. They can be used in high temperature and low temperature, hig

XRD Graphite specializes in the production of graphite bearing, graphite hot zone, graphite rotors, graphite crucibles, graphite boats, graphite tubes, graphite rods, graphite baffles, graphite flow channels, graphite plates, etc.XRD Graphite's own special graphite production line can provide more than one hundred different specifications of graphite raw materials. According to the needs of different industries for different graphite materials, select specific materials for customers, after special treatment such as oxidation resistance, effectively extend the life of graphite machining products, improve product cost performance.

Graphite bearing introduction:

Graphite sliding bearings are mainly made of graphite, and have strong self-lubrication. They can be used in high temperature and low temperature, high speed and low speed sliding conditions. They can run for a long time without lubricating oil, and have corrosion resistance to gas and liquid medium with strong corrosion.

Application scope of graphite bearing

1. place where grease and lubricants are not permitted when running bearings.

For example, bearings used in the food, beverage, textile, chemical and other industrial sectors, dryers for the paper industry, cloth dryers for the textile industry, man-made fiber looms, cigarette manufacturing equipment and submersible pump machines. Oil lubricants are banned in these areas, and carbon-graphite bearings are highly self-lubricating and do not require lubricating oil for dry operation, so they can be widely used in these sectors.

2. it is used in places where ordinary bearings can not be used because of high temperature.

Carbon-graphite bearings can be used in ingot conveyors, boiler preheaters, flame tube ventilation doors and blowers in boiler rooms, high-temperature furnace conveyors, feeders in the iron and steel industry, and flue valve regulators to ensure their normal operation.

3. used in chemical and textile industries.

Some bearings operate in corrosive gas or liquids, where grease lubricants are prohibited and metal bearings are quickly corroded. For example, impeller bearings immersed in a variety of liquids in the operation of centrifugal pumps; bearings in gasoline, paraffin, kerosene and other liquids in the operation of fuel metering pumps; main impeller bearings immersed in hot water in the operation of the central thermal cycle pump; bearings in a variety of corrosive media in the mixer; main impeller bearings immersed in hot water in the operation of the main impeller bearings Carbon-graphite bearings are used in dynamic washing machines, liquid meters with bearings immersed in various liquids, and wet-spinning machines with bearings running on artificial fibers splashed. In addition, modern technology also requires carbon graphite bearing to be used safely in complicated radioactive medium.

Advantage of XRD graphite's graphite bearing products:

Selection of raw materials:

Special graphite developed by XRD Graphite specialty is used as raw material, which has high mechanical strength, good self-lubrication performance, high temperature creep resistance, high coefficient of friction, high coefficient of thermal conductivity and low coefficient of thermal expansion.

Product processing:

strictly according to the customer's drawings of high-precision processing, the installation of each component closely with each other, high concentricity;

Impregnating and anti-oxidation:

the raw materials were treated with anti-oxidation by many times of impregnation and roasting, so that the graphite materials were filled with anti-oxidants and the surface was covered with anti-oxidants, which effectively improved the high temperature resistance, anti-oxidation, anti-erosion performance of graphite bearings, and greatly prolonged their service life.

XRD Graphite focus on supply large quantities of stable quality graphite products to customers with graphitization or graphite machining needs. To date, XRD Graphite has forged lasting relationships with key customers in over 30 countries and be considered as one of the leading supplier of graphite manufacturing and machining products in China. XRD Graphite is to constantly provide superior customer service while delivering stable quality graphite products in mass production.