|

XRD Graphite Manufacturing Co., Ltd.

|

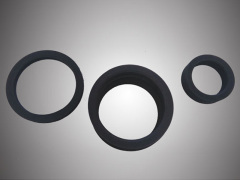

Anti oxidation graphite rotor

| Price: | 100.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

XRD Graphite's Antioxidant Graphite Rotor

XRD Graphite specializes in the production of anti-oxidation graphite rotors, graphite crucibles, graphite boats, graphite tubes, graphite rods, graphite baffles, graphite flow channels, graphite plates, etc.XRD Graphite's own special graphite production line can provide more than one hundred different specifications of graphite raw materials. According to the needs of different industries for different graphite materials, select specific materials for customers, after special treatment such as oxidation resistance, effectively extend the life of graphite machining products, improve product cost performance.

Anti-oxidation graphite rotor introduction:

The liquid aluminum alloy purification treatment process is the main means to improve the comprehensive performance of aluminum alloy. In the purification treatment process, the purification gas and the solvent are mixed, and the method of purifying the aluminum melt by the rotary injection of the graphite rotor is the most advanced treatment method in the world. The working principle of the graphite rotor is that the rotating rotor breaks the nitrogen (or argon) blown into the aluminum melt into a large amount of dispersed bubbles and disperses it in the molten metal. In the melt, the gas is separated by the partial pressure difference of the gas and the surface adsorption principle, absorbs the hydrogen in the melt, adsorbs the oxidized slag, and is taken out of the surface of the melt as the bubble rises, so that the melt is purified. Due to the fine dispersion of the bubbles, it is uniformly mixed with the rotating melt, and then rotates in a spiral shape and slowly floats. The contact time with the melt is long, and the gas flow generated by the continuous straight rise is not formed, thereby removing harmful hydrogen in the aluminum melt, which is remarkable improve the purification effect.

Advantages of XRD Graphite's Antioxidant Graphite Rotor:

Material selection:

using special graphite developed by XRD Graphite as raw material, high purity, high strength, high hardness, oxidation resistance, low porosity, abrasion resistance and erosion resistance.

Product processing:

High-precision processing in strict accordance with customer's drawings. After installation, the components are closely matched and have high concentricity, effectively avoiding mechanical stress damage.

Special treatment:

Impregnation for anti-oxidation:

The anti-oxidation treatment is carried out on the raw materials by multiple impregnation roasting, so that the micropores inside the graphite material are filled with anti-oxidant and the surface is covered with antioxidant, which effectively improves the high temperature resistance, oxidation resistance and erosion resistance of the graphite rotor. Extend its service life;

Coating resistance:

The surface of the graphite rotor after impregnation and oxidation treatment is coated with high-efficiency coating material. The coating material can be firmly combined with graphite material and is more resistant to high temperature and oxidation than graphite material. Wear-resistant, wash-resistant, coated graphite rotor, the service life is further extended;

Local enhancement:

According to the characteristics of the end user, the most easily consumed part of the graphite rotor is locally enhanced to achieve the longest service life at the lowest cost.

XRD Graphite focus on supply large quantities of stable quality graphite products to customers with graphitization or graphite machining needs. To date, XRD Graphite has forged lasting relationships with key customers in over 30 countries and be considered as one of the leading supplier of graphite manufacturing and machining products in China. XRD Graphite is to constantly provide superior customer service while delivering stable quality graphite products in mass production.