|

XRD Graphite Manufacturing Co., Ltd.

|

high purity and fine-grain graphite materials

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

All the material are high purity graphite and fine-grain, as a graphite manufacturer who can provide stable supply for big customer, we have uniform s

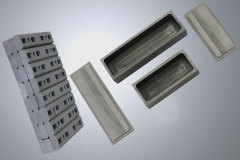

PLEASE NOTE: All the material are high purity graphite and fine-grain, as a graphite manufacturer who can provide stable supply for big customer, we have uniform shaped graphite rods and graphite blocks in stock all the time.

The molding method is to load a certain amount of paste into a mold having a desired shape and size and then press it from the upper or lower portion. Sometimes, a certain pressure is applied to the paste from both the upper and lower directions, so that the paste is compressed and formed in the mold. The pressed semi-finished product is then inspected by demoulding cooling. Then pile it up. Molding equipment has vertical presses and horizontal presses. Molding method generally only presses one product at a time, and the production efficiency is relatively low. But it can make products that cannot be made by some extrusion methods. Molded graphite has a wide range of properties in terms of mechanical strength, abrasion resistance, density, hardness, electrical conductivity, etc., and can be further improved by impregnating a resin or a metal.

Features

XRD's molded graphite products demonstrate advantages over industry standard products, indcluding:

Strong Thermal Stability,

Low Expansion Ratio,

Excellent Chemical Resistance,

Self-lubricating,

High purity,

Excellent thermal shock properties,

High temperature and oxidation resistance,

Good anti-corrosion,

Excellent Electrical Conductivity and Thermal Conductivity,

Good Machinability.

Properties Data

XRD Graphite GradesApplicationsBulk DensityElectrical ResistivityHardnessFlexural StrengthCompressive StrengthPorosityAsh ContentAsh Content(Purified)Average Grain Size

| g/cm3 | μΩm | HSD | Mpa | Mpa | % | PPM | PPM | μm | ||

| xrd-4w | General Purpose | 1.75 | 8-11 | 42 | 38 | 65 | 17 | 500 | 50 | 14 |

| xrd-5w | General Purpose | 1.85 | 8-10 | 48 | 46 | 85 | 13 | 500 | 50 | 14 |

| xrd-5r | EDM | 1.68 | 13-13 | 51 | 38 | 86 | 18 | 500 | 50 | 14 |

| xrd-10w | EDM,Photovoltaic | 1.76 | 12-14 | 56 | 41 | 85 | 16 | 500 | 50 | 12 |

| xrd-20b | General Purpose | 1.58 | 12-16 | 35 | 22 | 45 | 23 | 1000 | 50 | 15 |

| xrd-30b | General Purpose | 1.71 | 10-15 | 38 | 28 | 50 | 20 | 1000 | 50 | 15 |

| xrd-40b | General Purpose | 1.80 | 8-11 | 42 | 38 | 66 | 17 | 1000 | 50 | 15 |

| xrd-50b | General Purpose | 1.86 | 8-11 | 50 | 46 | 96 | 13 | 900 | 50 | 15 |

| xrd-60b | General Purpose | 1.90 | 8-11 | 55 | 55 | 100 | 12 | 800 | 50 | 14 |

| xrd-20h | null | 1.58 | 12-16 | 35 | 23 | 50 | 23 | 1500 | 50 | 15 |

| xrd-30w | General Purpose | 1.70 | 10-15 | 38 | 28 | 50 | 20 | 1000 | 50 | 12 |

| xrd-40w | EDM | 1.72 | 12-16 | 52 | 40 | 86 | 18 | 1000 | 50 | 8 |

| xrd-20s | Bearing | 1.47 | 12-16 | 30 | 18 | 38 | 25 | 1000 | 50 | 15 |

| xrd-40s | General Purpose | 1.78 | 8-11 | 42 | 38 | 66 | 18 | 1000 | 50 | 12 |

| xrd-40d | EDM | 1.73 | 12-16 | 52 | 40 | 86 | 18 | 1000 | 50 | 13 |

| xrd-50d | EDM | 1.83 | 12-16 | 65 | 50 | 102 | 13 | 900 | 50 | 10 |

| xrd-60d | EDM | 1.88 | 12-16 | 70 | 60 | 118 | 12 | 800 | 50 | 8 |

| xrd-10tw | null | 1.60 | 30-40 | 60 | 28 | 90 | 25 | 3000 | 50 | 8 |

| xrd-3k | Home Appliance,Crucible | 1.68 | 9-13 | 35 | 20 | 45 | 18 | 600 | 50 | 15 |

| xrd-5k | Sintering,EDM | 1.80 | 8-10 | 48 | 35 | 70 | 13 | 500 | 50 | 15 |

| xrd-5ks | Continuous Casting,Sintering,EDM | 1.85 | 8-10 | 55 | 40 | 80 | 12 | 500 | 50 | 15 |

| xrd-10k | EDM | 1.75 | 10-14 | 50 | 38 | 75 | 12 | 500 | 50 | 4 |

| xrd-20k | EDM | 1.85 | 11-15 | 65 | 50 | 110 | 11 | 500 | 50 | 4 |

1. The figures above are typical values, and to be considered minimum or maximum.

2. Unit conversion: μΩ•m=μΩ•cm×0.01 MPa=kgf/cm2×0.098 GPa=kgf/mm2×0.0098 W/(m•K)=kcal/h•mºC×1.16

3. There are other product sizes in addition to those described above. Contact XRD Graphite for more details.

Application

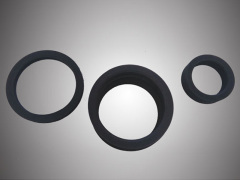

Molded graphite is widely used in aerospace, solar photovoltaic and semiconductor, continuous casting, hard alloy and electronic mold sintering, EDM, glass, pharmaceutical and other industries.

aerospace

solar photovoltaic and semiconductor

continuous casting

hard alloy

electronic mold sintering

EDM

glass

pharmaceutical